Pallet Separator, Ergo Cell Lift Table

Mallard Manufacturing, a manufacturer of gravity flow storage products, has introduced a wireless control pneumatic pallet separator and Ergo Cell lift table.

The pneumatic separator holds back rear pallets in a pallet flow lane so that order pickers can safely pick cases from the front pallet. The lift table creates an ideal pick height limiting range of motion stresses for workers. Typically, a control box adjacent to the pallet flow lane triggers the pneumatic pop-up devices. With the new wireless control box, a forklift operator or order picker can engage the separator from inside the forklift cab or another location within the warehouse.

Efficiency and safety improvements for case pick lines

Wireless control while isolating the first pallet provides valuable safety protections for warehouse order pickers.

- The new wireless controller minimizes worker movement at a time when social distancing is of extreme importance. The workers can now release the separator from their pick position as opposed to moving to a stationary control box near the lane. The controller can even be used from within a forklift if the application applies.

- Eliminating the rear pallet back pressure on the front pick face pallet ensures that the worker can freely and more easily remove cases and the empty pallet. Back pressure can be considerable in a pallet flow lane depending on lane length and/or pallet load weights.

For example, in a 3-deep pallet flow lane with 2,500 lb. pallet loads, back pressure would be calculated as .06 x 2,500 lbs. x 2 pallets = 300 lbs. of extra pressure on the front pallet.

- Pairing the Ergo Cell separator with a hydraulically-powered lift table raises the first pallet up to an ergonomically-advantageous height from which the order picker can pull cases with minimal strain.

Pallet building with the ergo cell pallet separator

The Ergo Cell pallet separator can also be installed in the load side of the pallet flow lane to hold a pallet in place until it is loaded. The full pallet can then be released with the new wireless controller to flow down the lane for storage or eventual extraction.

“The Ergo Cell is a multi-faceted product that provides enhanced warehouse safety and improved ergonomics,” explains Kevin Risch, president of Mallard Manufacturing. “Our customers across a variety of sectors have experienced measurable productivity gains after integrating the pneumatic separator and lift table in their case-picking applications. We have recently expanded and updated our entire pallet separator line as we’ve seen application benefits expand particularly due to the rise in smaller, more customized order fulfillment.”

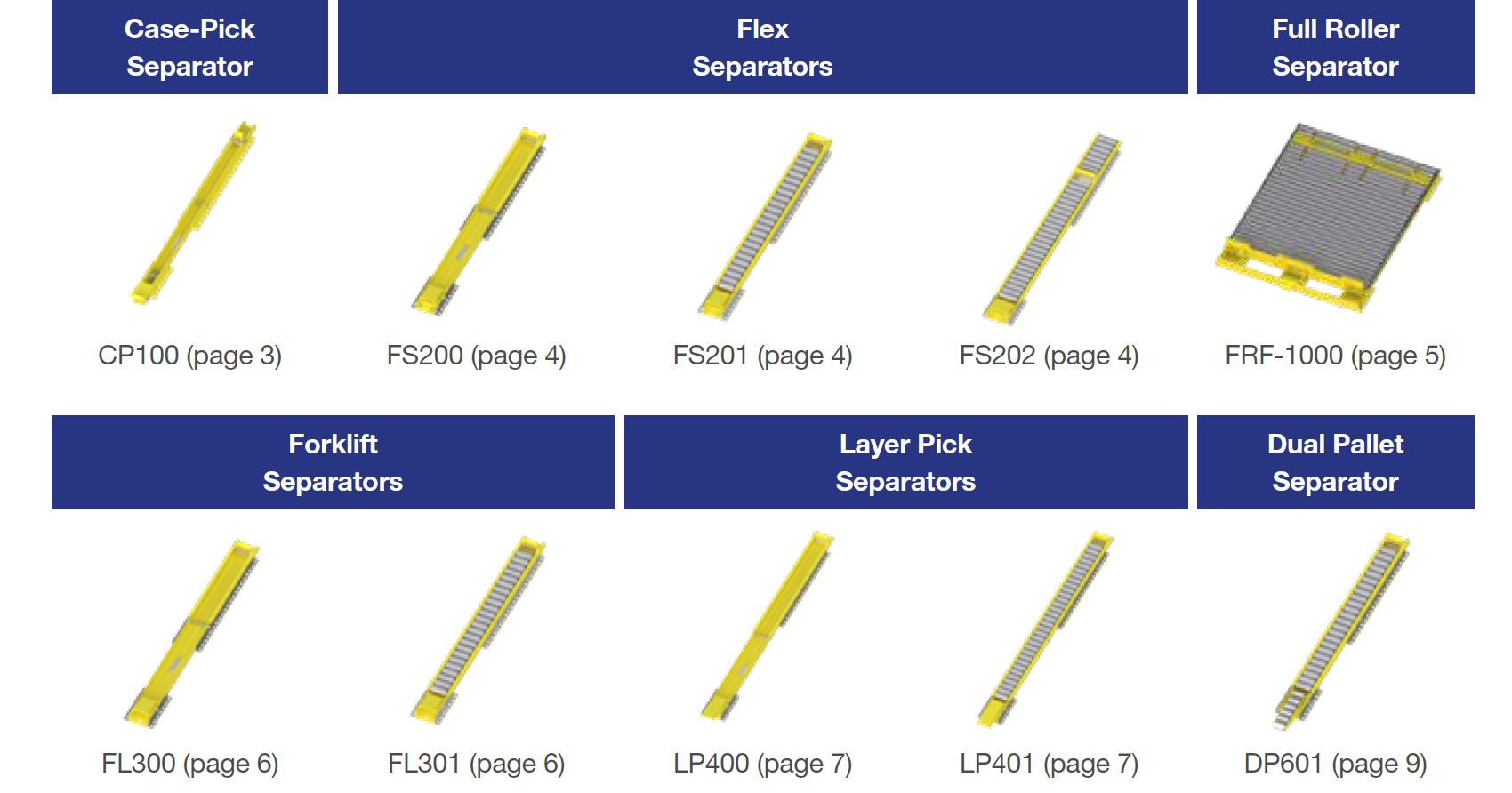

Pallet flow systems are used for a variety of warehouse needs. Each pallet separator is designed for specific uses and applications.

Mallard pallet separator line of products

Mallard pallet separators:

- Case-Pick Pallet Separator (CP Series)

- Flex Separator (FS Series)

- Forklift Separator (FL Series)

- Layer Pick Separator (LP Series)

- Ergo Cell Pneumatic Separator (PS Series)

- Dual Pallet Separator (DP Series)

- Empty Pallet Return (EPR Series)