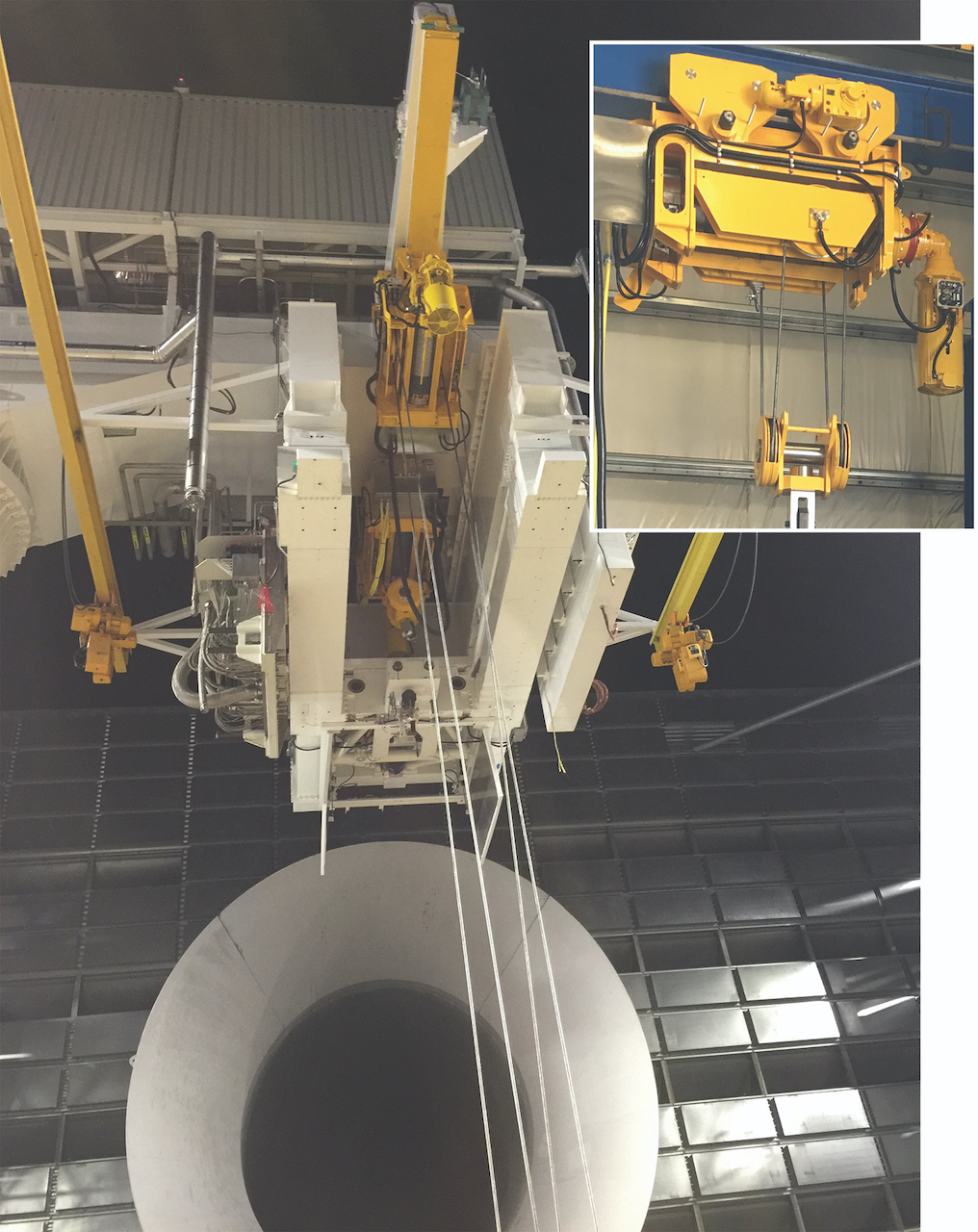

EMH Custom Hoist for Jet Engine Test Site

Engineered Material Handling (EMH) was contacted by Standard Aero, an international aircraft engineering firm, to develop a unique Jet Engine Test Stand for a GE cold weather test facility.

EMH was asked to help custom design and engineer a twin hoist application to hold GE jet engines in place at its cold weather test facility in Winnipeg, Canada, in support of manufacturing processes.

The hoist application had to be capable of precision operation in minus 40 degrees Centigrade. Special application engineering required specially designed heating for the motors and controls, special brakes, special fittings, special coatings, special seals and epoxy paint to protect it from intense cold and ice and snow build-up. All metals required charpy testing to make sure the metals would not fracture in bitter cold temperatures.

The twin hoist application holds jet engines in place at a cold weather test facility in Winnipeg, Canada.

Two EMH hoists were run in tandem and tested to 125% of their 50-ton capacity; 25-ton duty on each hoist. With intense cold, every facet of the hoist application had to be custom-engineered and required a factory 125% load test as well and witnessed by GE engineering. The motors were provided with VFD control and needed to operate at exceptionally slow speeds. The entire installation had to operate within very tight space constraints. According to Standard Aero’s Project Engineer, “We were extremely pleased how well EMH engineers collaborated with us on this very difficult one-of-a-kind custom installation.”

EMH, headquartered in Valley City, Ohio, designs, sells and manufactures a complete line of overhead material handling equipment for loads from 25 lbs. to 300 tons. EMH is ISO 9001:2015 certified.

Visit www.emhcranes.com