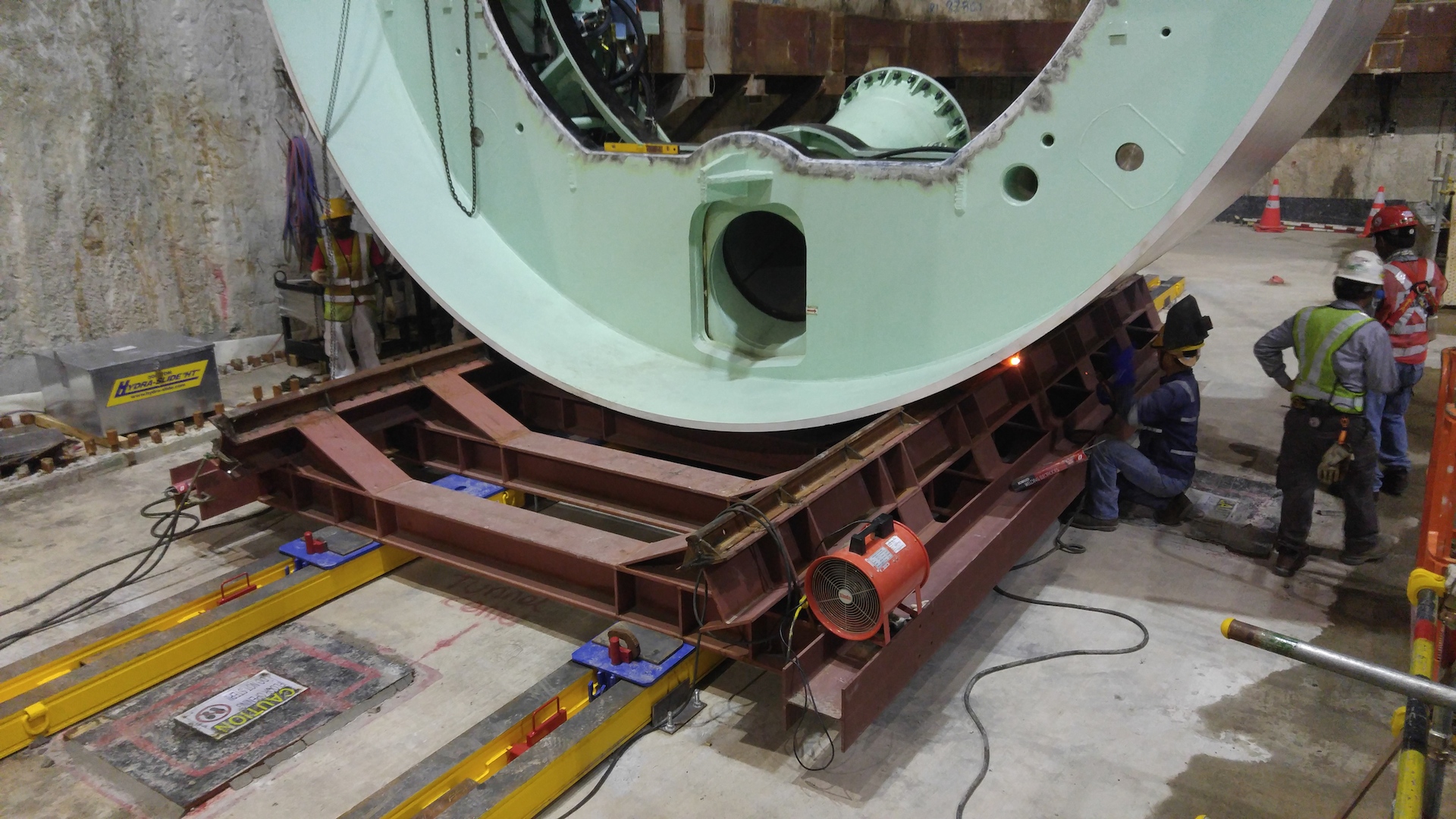

Yu Sin Engineering Uses a Hydra-Slide HT300 to Move Boring Machine for Singapore Tunnel Project

Yu Sin Engineering Work Pte Ltd skidded a tunnel boring machine underground during a major subway infrastructure project in Singapore last month (August).

The components of the tunnel borer were lowered down the 100ft (30m) shaft onto a Hydra-Slide HT300 hydraulically powered skidding system by the Terex AC700 crane at ground level. When completed, the fully assembled tunnel boring machine will be 22ft (6.96m) in diameter and weigh 461 ton in total. The new subway tunnel will be almost 2,000ft (600m) in length, connecting two areas of the city currently separated by water.

Contractor Yu Sin Engineering Work Pte Ltd from Singapore sought a solution to move the boring machine parts over a distance of approximately 66ft (20m) and connect them in the launch shaft. The machine could not be lowered directly onto its working path because of a major road over the tunnel entry point and other structural interferences.

Having discovered Canada-based Hydra-Slide online, Yu Sin was convinced that this was the right equipment for the job. Given the project time constraints, the 23,000lb (10,500kg) HT300 system travelled by cargo plane and then by truck to the jobsite. Shipments of this kind would more commonly travel by ocean with a transit time of about 45 days. In addition, Ekki hardwood jacking timbers supplied by Hydra-Slide were also air freighted directly from the mill in Holland to Singapore.

Robert Young, director of operations at Hydra-Slide, was onsite to provide training for Yu Sin personnel on the set-up and operation of the HT300 skidding system and witness the first slide of the boring machine components. He explained that despite the complexities involved with transporting the skidding equipment by Air to Singapore, no complications arose from utilizing the equipment underground.

Young said: “This is actually the perfect application for the HT system due to its modular design, light weight and ease of assembly. No extra ground testing was necessary as the bottom of the launch shaft was poured concrete that was capable of supporting the weight of the HT300 and loads. This was the first time our equipment was used to move a TBM [tunnel boring machine] and we see future potential in this area, especially after the success of this project.”

In addition to the standard HT300 skid system, Hydra-Slide’s scope of supply included provision of specially designed skid shoe extensions, which allowed the boring machine’s base full contact support with the skid system.

Jefferson Yee, general manager at Yu Sin, said the front body assembly consisted of six pieces weighing 241 tons in total, which were lowered into the launch shaft and assembled on the HT300 skid system. It comprised the front body bottom (34 tons), bearing (98 tons), front body top (32 tons), cutter head (64 ton), working deck and man lock, which together added another 13 tons of weight.

Yee explained that after the front body was slid into place, the middle body was lowered in one 128-ton piece, followed by the 64 ton rear body and, finally, the two-part screw conveyor that weighed 28 tons. At the end of each slide, the sub-assemblies were pulled onto the launch cradle using hydraulic jacks and connected together.

He concluded: “The project was a huge success. I would like to thank the Hydra-Slide team for helping us achieve our goals for the installation of the TBM.”

The project is scheduled for completion in 2018.