SmartControl for VRCs

Material handling equipment and safety products manufacturer Wildeck Inc. has introduced a new material lift control system. SmartControl for hydraulically-operated vertical reciprocating conveyors (VRCs) protects a customer’s investment by sensing when one of a dozen or more faults occur.

The SmartControl system immediately sounds an audible alarm specific to the fault condition. This saves precious time for the operator to quickly identify the fault and make necessary corrections before the lift or its cargo are damaged.

Key VRC SmartControl features include:

- Fault-specific audible alarm (with adjustable horn volume).

- Large placard at the control panel, and at each station to describe the fault condition.

- Accurate solid state hydraulic pressure sensor replaces mechanical pressure switch. No more adjustment or maintenance required.

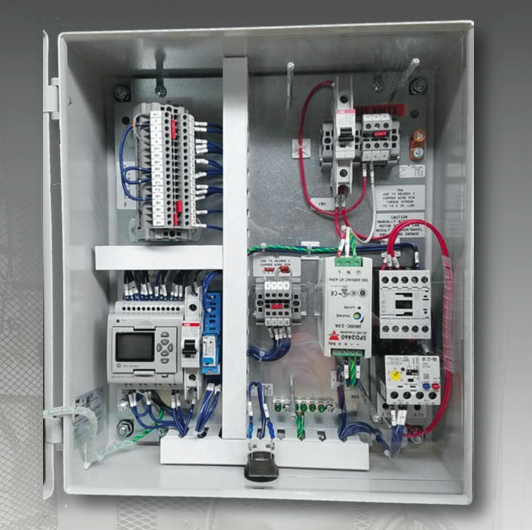

- “Smart” Allen-Bradley PLC (programmable logic controller) pre-programmed with Wildeck’s patented AutoSenz software (U.S. Patent No. 7,408,317) for automatic jam sensing and VRC overload protection.

- Extensive system diagnostics and VRC fault detection, including over-capacity, open gates and their location, VRC jams, hydraulic pressure, pump motor status, and more.

Hue Schlegel, Wildeck’s director of marketing, said: “Old controls had relay logic that stopped the VRC on an error without signaling the cause of the fault or what to do about it. Did the unit stop because it had too much weight? Did the pump run out of hydraulic oil? Did someone push the E-Stop button? Wildeck’s SmartControl system eliminates all of this guesswork and time-wasting troubleshooting. With fault-specific audible alarms and an internal digital panel that helps maintenance personnel quickly examine fault history, issues are immediately identified for rapid resolution allowing the lift to be back in service in the shortest amount of time.”

VRC Fault history is conveniently saved in the SmartControl PLC’s memory while error messaging can be easily accessed on a digital panel inside the control cabinet for quick diagnosis by a qualified technician or an electrician.

The control and diagnostics system will be shown for the first time in Booth S1012 at ProMat 2017, which takes place 3-6 April at Chicago’s McCormick Place.