DLM Meets Demand for Large-Batch Load Pin Orders

Dynamic Load Monitoring (UK) Ltd. (DLM) is utilizing an expanded machine shop to supply custom load pins — including bulk orders — for global subsea cable laying applications.

The Southampton-based company is a longtime supplier of load cells, load monitoring technology, and cable working equipment to the lifting, rigging, wind energy, and wider renewables sector. However, it recently upgraded its machine shop in Vancouver Wharf to meet increasing demand for load pins from subsea cable lay vehicle and deck equipment manufacturers.

Although a common order might be for one to three pins, larger batches are becoming more frequent.

Load pins always feature a custom design element and vary greatly in capacity from 1t up to DLM’s largest to date, which was a 2,800t feat of engineering. At the lower end of the scale, pins are generally for subsea use, while larger products are typically for pipe laying towers in the oil and gas sector. Land-based cranes, on-deck cable tensioners, winches, and launch and recovery systems (LARS) feature load pin components too. Inevitably, much of this equipment is manufactured for use in hazardous ATEX and IECEx environments.

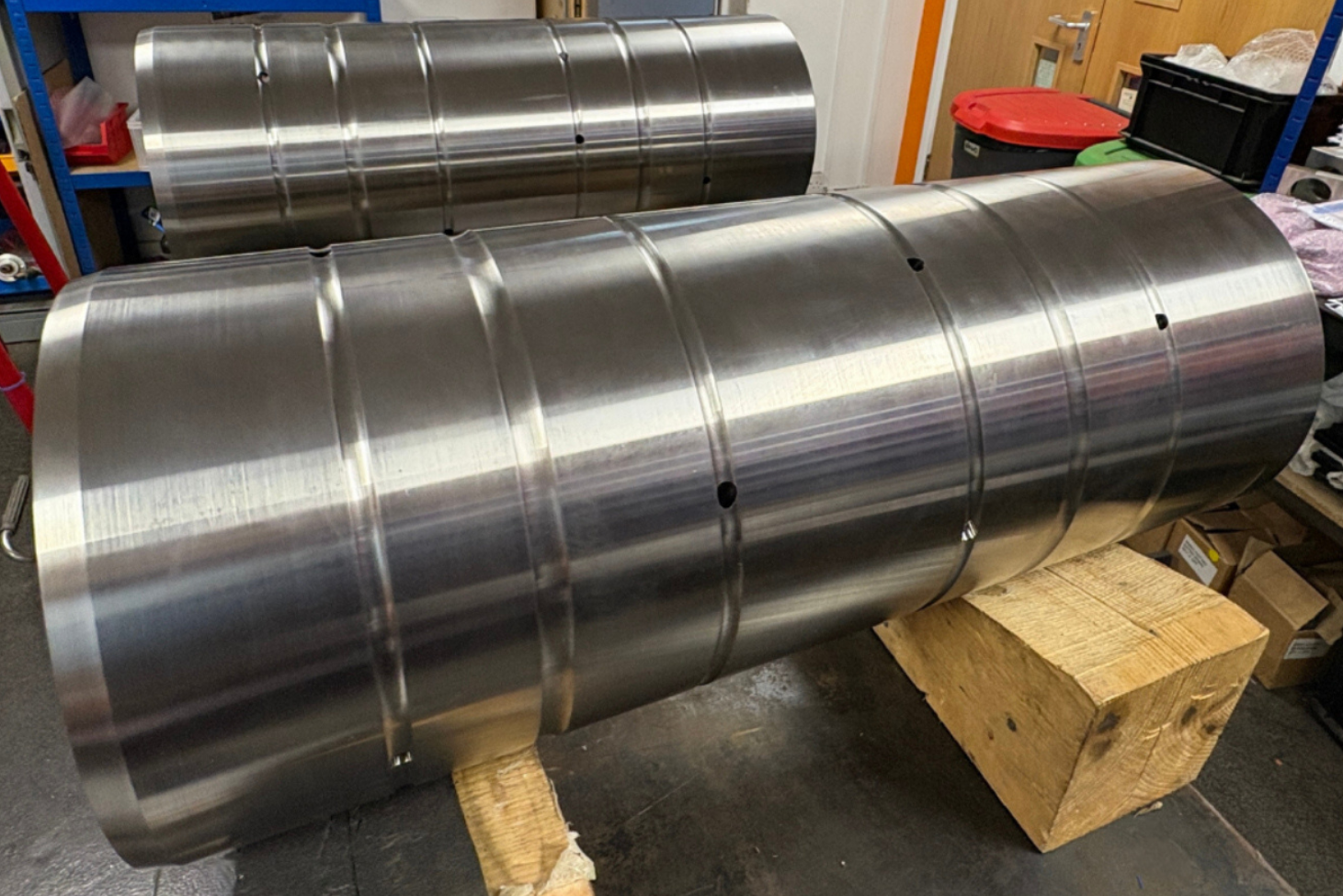

An expanded machine shop allows DLM to supply bulk orders for custom load pins.

Martin Halford, managing director at DLM, said: “It is a fast-moving and challenging supply chain that only a certain type of manufacturing business can serve. The capability of our expanded suite of machining and milling equipment has been well documented, but with good reason — without it, we wouldn’t be able to machine larger pins, or meet demand for larger batches, which is more commonly a requirement from customers working with cable installers.”

Custom load pins are commonly delivered to global subsea cable laying projects.

A Doosan Puma 3100LY computer numerical control (CNC) lathe is the centrepiece of a machining fleet that also includes a second lathe, a mill, and a ban saw. The lathes are in near constant use; while there are standard design concepts and processes, typically the external length, diameter, connector type, and electrical output on a load pin are specific to the client’s requirements. Although a common batch might be for one to three pins, larger orders are more frequent.

Load pins always feature a custom design element and vary greatly in capacity. Typically, the external length, diameter, connector type, and electrical output on a load pin are specific to the client’s requirements.

Halford continued: “Having the machine shop has helped enormously with order fulfilment and lead times. We might have up to eight weeks to supply a load pin for a newly manufactured vessel, but much less when supporting operational projects that are going live. Ahead of a cable lay operation, the client will want to have a full range of spares onboard, so that expensive downtime can be avoided if something gets damaged in operation.”

The new lathe enables DLM to machine larger pins, both in length and diameter; the product also has a Y-axis, enabling high volume machining to greater detail. In many instances, operatives can machine whole load pins without removing them from the lathe. The Y-axis allows DLM to complete milling operations that traditionally would have been completed on a mill — adding complexity and time to the manufacturing process.

DLM is utilizing an expanded machine shop to supply custom load pins.

DLM’s current order book includes load pins for single point mooring (SPM) buoys, which are floating offshore systems anchored to the seabed; and to measure tension on hawsers, the heavy-duty mooring cables used to connect oil and gas tankers to such SPM buoys. Many pins are fitted internally with DLM’s 4-20mA amplifier, but they can be paired with TW-3.0 standard or telemetry displays, if the pin is fitted with a telemetry transmitter. They can also be supplied as part of a larger programmable logic controller (PLC) system.

Halford added: “There is an abundance of cable being laid around the world for both fibre optic [internet] and power installation [wind energy] projects. With the current upsurge in orders, we will be investing in more testing and manufacturing machines. We have nearly five times the booked order value than what we had at the start of the year — and double what we had this time last year. It is the highest order input we have ever had in our history.”